Load cells and force sensors engineered and manufactured by Stellar Technology can be found in industrial applications all over the world. These include market sectors such as aerospace, oil & gas, automotive, automation & control, medical and many more.

Custom-Designed Load Cells

We also specialize in custom-designed force sensors and load cells for your unique applications. Our engineers communicate directly with your team to ensure that every load cell specification or force sensor design meets your exact application needs.

Customers know that they can rely on Stellar Technology’s engineering experience and our state-of-the-art manufacturing capabilities to get the exact load cell or force sensor they need. We also provide expert technical support (including on-site technical assistance) and responsive service after-sale to keep your project on schedule.

At Stellar Technology, we are proud to give you one of the best selections of stocked and standard load cells in the industry. Our load cell types can range from a few grams to two million pounds compression operation or tension, and the accuracies are up to 0.03%. When it comes to load cell manufacturers, Stellar Technology proves to be an industry leader with a solution for each and every application.

Our proprietary electronics give you high-level mV/V, along with digital and analog outputs including RS485, RS232, and CANbus. The fully welded, and stainless-steel construction means the load cells can withstand the rigors of all applications. If you are looking for the highest-quality load cells and force sensors, Stellar Technology has got you covered.

Stellar Technology Load Cells and Force Sensors

Stellar Technology’s combination of proven sensor technology, engineering expertise, field experience, and manufacturing capability is exceptional among manufacturers of load cell in the industry and offers our customers high-reliability and high-performance load cells for a variety of applications.

Our wide variety of load cell types can be found in industrial applications all over the world. These include market sectors such as aerospace, oil & gas, automotive, automation & control, medial and many more. We can provide fatigue-rated designs, submersible units, and load cells with multiple outputs, plus intrinsically safe models.

As a top-rated load cell manufacturer, Stellar Technology also offers select load cells in stock for immediate delivery. Select from:

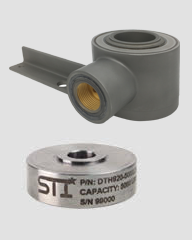

Pancake Load Cells

- Tension-compression pancake load cells that have high accuracy

- Coiled tubing pancake load cells

- Precision pancake, fatigue-rated load cells

Canister Load Cells

- Compact, rugged canister load cells

- High-accuracy, high-capacity, tension and compression load cells

- High-accuracy, high-capacity, load cells with internal amplifier

Miniature Load Cells

- Precision miniature tension and compression load cells

- Miniature tension and compression load cells

- High-capacity miniature tension and compression load cells

Subminiature Load Cells

- Subminiature tension and compression load cells

- Subminiature compression load cells

Rod End Load Cells

- In-line rod end load cells

- Compact high-capacity rod end load cells

Thru-Hole Load Cells

- Low-profile, thru-hole load cells

- Pump-off control

Beam Load Cells

- Ultra-low profile

- Accuracy of .10%

- Tension and compression

- Output of 2 mV/V

- All-welded stainless-steel build

- Standard temperature range of -40°F to 250°F

- Shock and vibration resistant

- 9-point calibration record traceable to NIST

Clevis Pin Load Cells

- Intrinsically safe

- Submersible units can withstand up to 16,000 ft. of seawater

- Standard operating temperature range of -65°F to +250°F or -320° to +400°F optionally available

- All-welded stainless steel

- Hermetically sealed

- Shock and vibration resistant load cells

- 5-point calibration record traceable to NIST

Choosing the Optimal Force Sensor or Load Cell Types

There are a number of factors you need to keep in mind when considering a load cell manufacturer to choose for help in finding the best-suited load cell or force sensor for your application. These considerations can range anywhere from accuracy and physical restraints to environmental conditions such as temperature and hazardous elements. Let Stellar Technology provide you with the optimal force sensor and load cell solutions.

Here are a few of the major load cell aspects you should keep in mind during your search:

Performance Considerations

When looking for a load cell or force sensor to fit your application, it’s important to know the level of performance you need the unit to reach. Does the job require specific conditions or does it need to measure certain weight or load limits?

Here are a few of the questions regarding load cell performance considerations you should be aware of:

- What is the maximum load, weight or force you intend to measure?

- What are the loading conditions for this application – is it compression, tension, both, or multi-axis?

- What type of engineering units do you require? (tons, grams, pound-force, newtons, etc.)

- What type of loading conditions will this sensor encounter?

- Are you searching for thermal accuracy, static accuracy, or total accuracy?

- Overloading (exceeding maximum load) and by how much?

- Static overload capacity – what safety factors should you take into account?

- Dynamic loading – will it encounter these types, which can exceed anticipated static loads?

- Fatigue loading (high cycle rates)?

- Off-axis loading (side loads)?

Mechanical Considerations

- What are the physical requirements?

- Size constraints

- Orientation

- Location access

- Submersible

- What are the configuration specifications – does the application require a certain load cell style?

- Rod end

- Pancake

- Load pin

- Miniature

- Beam style

- Thru-hole/donut

- Canister

- Load washer

- What types of loading requirements are there?

- Threaded

- Clevis pin

- Tongue shackle

- Load button

- Special configuration

Electrical Considerations

- What is the electrical output from the sensor?

- Is it analog?

- Is it digital?

- Is it a combination of the two?

- What type of electrical termination does it use – does it need additional equipment?

- Connector, integral cable, flying leads

- Mating connectors and cable assemblies

- Connector/cable orientation

- What are the external zero and span potentiometers?

- Wiring codes and pin-outs

- Does your application require DIN rail mount or in-line signal conditioning?

Environmental Considerations

- What is the temperature range for operation?

- What is the compensated temperature range?

- What are the EMI/RFI conditions?

- Will it be kept in a hazardous environment?

- Is a NEMA or IP rating required?

- Is it intrinsically safe?

- Is it explosion-proof?

- Will it be used indoors or outdoors? How will it respond to:

- Exposure to the elements

- Dust and dirt

- Extreme temperature

- Animals, critters, rodents, etc.

- Is the sensor submersible?

- Fresh or salt water

- Depth

- Case pressure

Special Requirements

- Does it have any specific calibration requirements?

- Do you need specific certifications or approvals?

- What are the requirements regarding testing or cleaning?

- Are there any special labeling requirements?

- What are the frequency response requirements?

- Is it shock- and vibration-resistant?

- What is its serviceability?

- How accessible must the unit be?

- How often will it be serviced?

Keeping all of these considerations under advisement as you begin your load cell or force sensor search will ultimately make for a more worthwhile purchase. If you are still unsure about which force sensor or load cell type is right for you, reach out to Stellar Technology today with any questions!

The Stellar Technology Load Cell Difference

Since Stellar Technology load cells and force sensors are designed and manufactured in our state-of-the-art, facility, in Amherst, New York we can offer a wide variety of products for any application need. With our combined knowledge of our sales personnel, engineering design expertise, and load cell manufacturer capabilities, we can guarantee that our customers are receiving maximum value and best experience possible.

Stellar Technology strives to be the leader in load cell and force sensor technology. Our top-quality products are seen in a many different applications all over the globe. Our variety of load cell types and force sensors are used in a number of market sectors across the industry.

Contact the Industry-Leading Load Cell Manufacturer Today

If you are interested in learning more about Stellar Technology’s wide variety of load cells and force sensors, we encourage you to contact us today. Let us help you find the solution that best fits your application needs. We look forward to hearing from you!